Cummins reintroduced its six-cylinder “X15” in Germany, but at Work Truck Week, the U.S. event dedicated to the road transport sector. It unveiled the new “B7.2” unit, showcased at its maximum output of 340 horsepower

Developed to cover the widest possible range of applications within the medium-duty segment, the new Cummins “B7.2” will be introduced to the North American market starting in 2027 as a replacement for the current “B6.7” engines.

The fundamental objective is to offer a high-performance yet environmentally friendly engine, as the unit is built on the “Helm” platform—“Higher Efficiency, Lower Emissions, and Multiple Fuels”—introduced by Cummins in 2024 to enable the creation of efficient, low-impact powertrains. This engine boasts the largest displacement among the “Helm” technical solutions, while retaining a six-cylinder inline architecture, with bore and stroke dimensions set at 107 millimeters by 133.

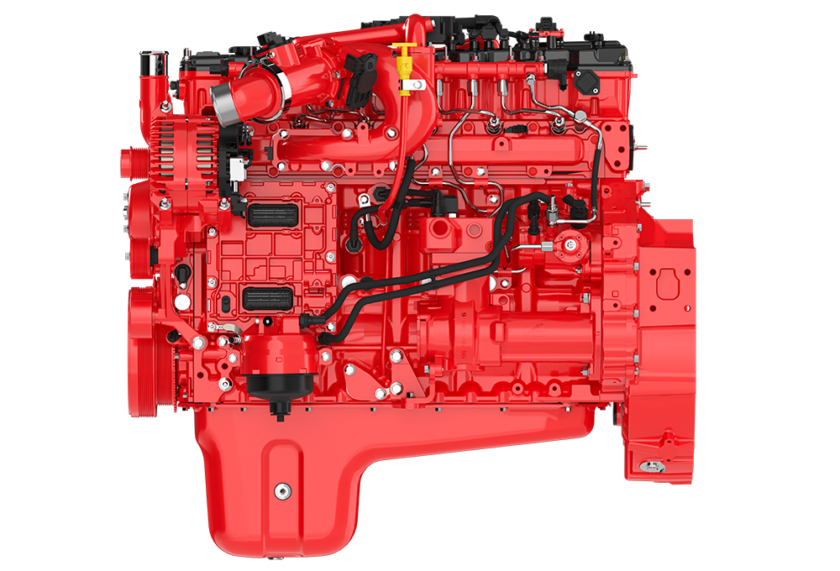

Cummins B7.2 unit

The larger displacement allows for a power range between 179 and 254 kilowatts, or 240 to 340 horsepower, with torque starting at 881 newton-meters and reaching up to 1,356 newton-meters, and an operating range that can reach up to 2,400 rpm. The unit is therefore not just a replacement for the “B6.7”, but is also capable of encroaching on applications traditionally served by high-displacement engines used in heavy-duty vehicles.

This achievement is made possible through combustion optimization, the refinement of a high-pressure direct injection common rail fuel system, and a racing-inspired valvetrain with dual overhead camshafts operating four valves per cylinder.

It’s worth highlighting the standard inclusion of a compression-release engine brake system that acts on the exhaust valves upon accelerator release.

This system forces the valves to open near the end of the compression stroke, allowing compressed air from the piston to be released. As a result, the engine absorbs energy from the wheels to compress air, but this air does not then create the spring-back effect (which occurs with closed valves) that would return some of the absorbed energy to the wheels. The outcome is stronger vehicle deceleration and reduced brake usage.ù

Performance is further supported by a Holset turbocharger, while emissions control is handled by an exhaust gas recirculation system with an integrated heat exchanger and a new aftertreatment system. The “Helm” platform also includes features such as a belt-driven 48-volt alternator that doubles as a starter motor, optimized oil change intervals, and Cummins’ complete suite of digital technologies.

Title: Cummins B7.2 unit: 340 horsepower

Translation with ChatGPT